Work Experience

Placement Year at Air Products

Completed a 13 month industrial placement at Air Products, a Fortune 500 company, gaining experience in process optimisation, monitoring systems and engineering standardisation.

Key Achievements

Designed and implemented condition monitoring logic, rolled out across 15 European plants.

Used Python and Excel VBA to automate monthly reviews, converting historian data into 30+ KPIs and 10+ safety/alert scenarios.

Built interactive dashboards that visualised performance, safety alerts, and plant efficiency in real time.

Established a tagging and naming convention that standardised metric formulas and enabled replication across European plants.

Standardised 250+ AutoCAD P&IDs and legend sheets for consistency across projects.

Conducted troubleshooting and root cause analysis (RCA) on site, wrote management reports with recommended actions.

Collaborated with several teams including IT departement, process control engineers, speciality gas engineers, and operations.

Expanded chemical engineering knowledge in covering mass and energy balance, thermodynamics, heat transfer, fluid dynamics and compressible flow, phase behaviour, pressure systems and process safety.

Company Representation

Represented Air Products at Cardiff University’s BCECA Industry Day. Delivered workshops on project lifecycle topics including bidding, scheduling, and risk management. Engaged with students to share industry practices.

Education

Higher Education

Completing a Bachelor’s in Mechanical Engineering with a year in industry at Nottingham Trent University (Sep 2022 – Jun 2026), with an expected First Class grade.

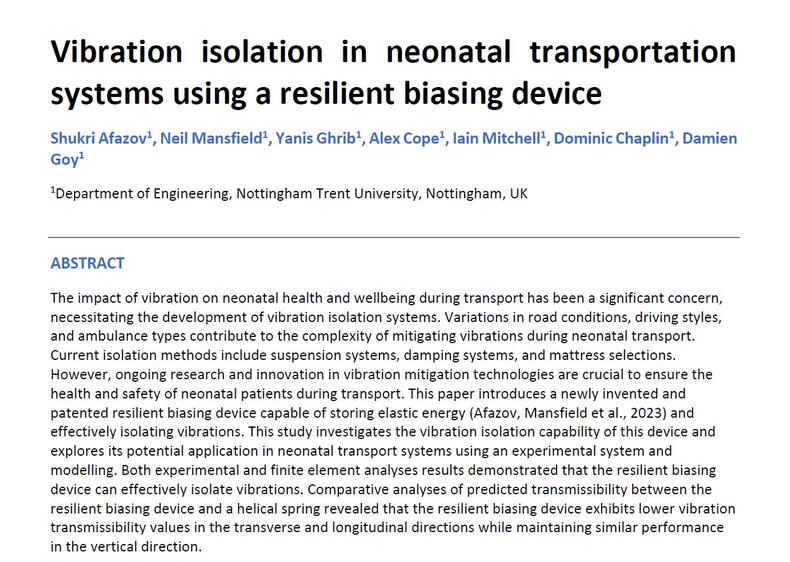

Engineering Research Internship

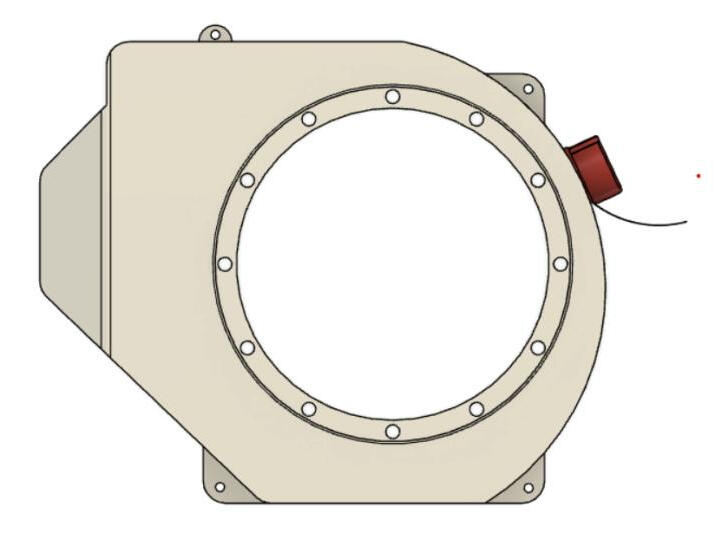

Completed a research internship focused on vibration isolation for neonatal transport where I designed a research assembly and test rig in Fusion 360, producing detailed engineering drawings, a bill of materials, and a full manufacturing pack. I supported workshop manufacture and assembly by performing measurement and fit checks, resolving build issues, and updating drawings through revision control, prepared a technical summary for the research team, earning acknowledgement as a contributor to the project.Link to the scientific article:

Vibration isolation in neonatal transportation systems using a resilient biasing device

Projects

Projects

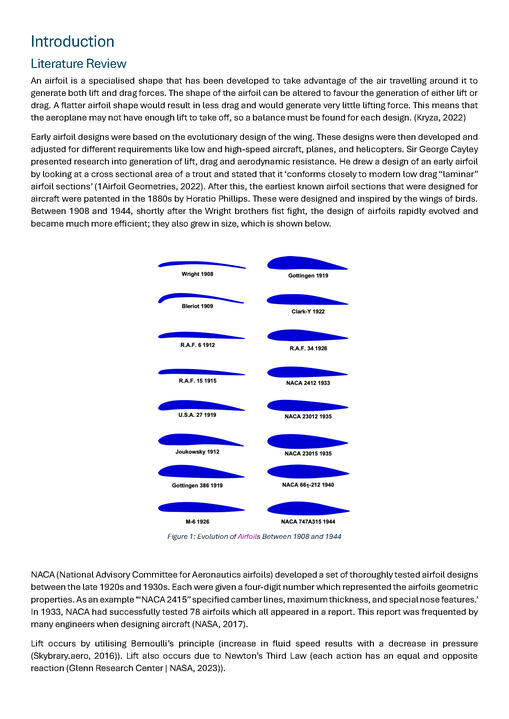

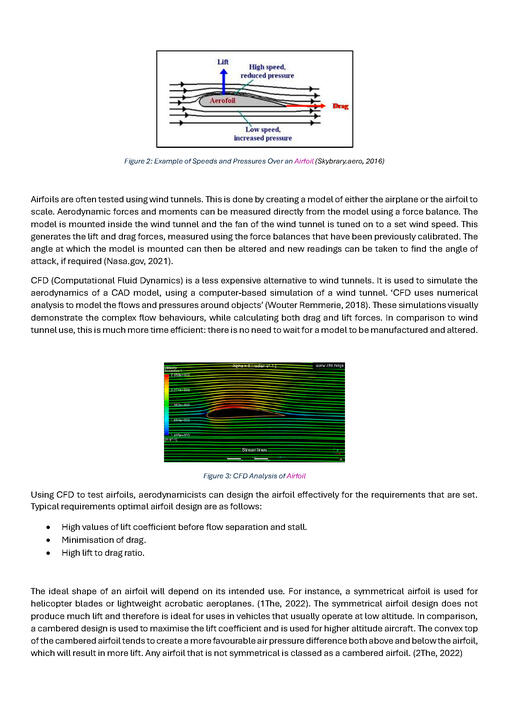

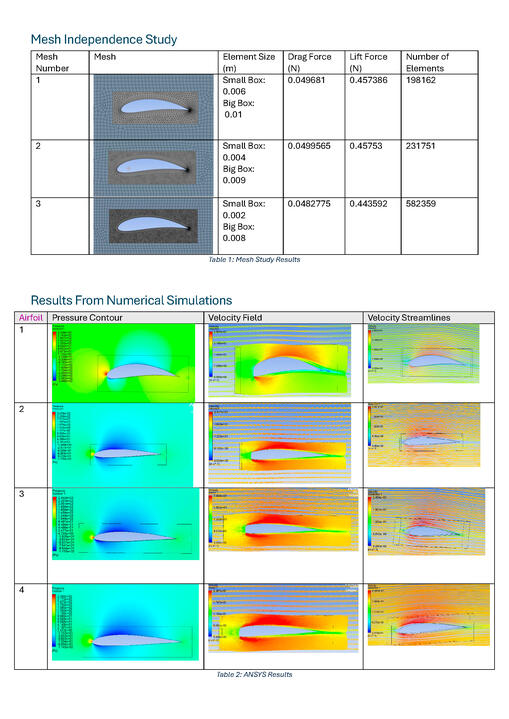

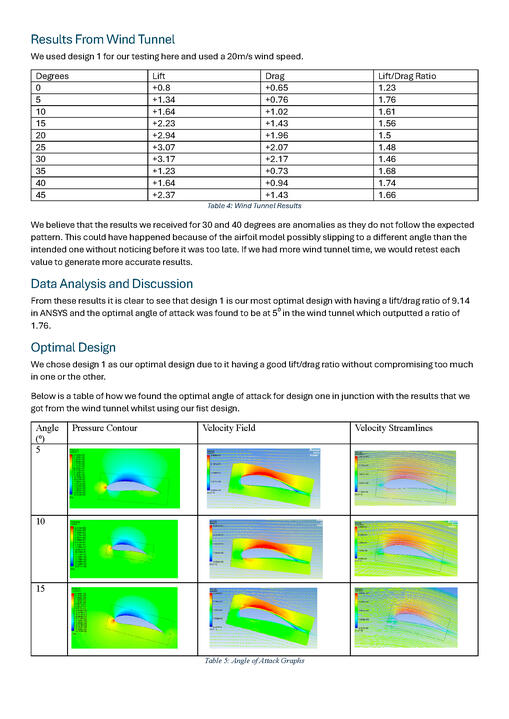

Airfoil design and testing Modelled candidates in ANSYS CFD, ran a mesh independence study and validated lift and drag in a wind tunnel

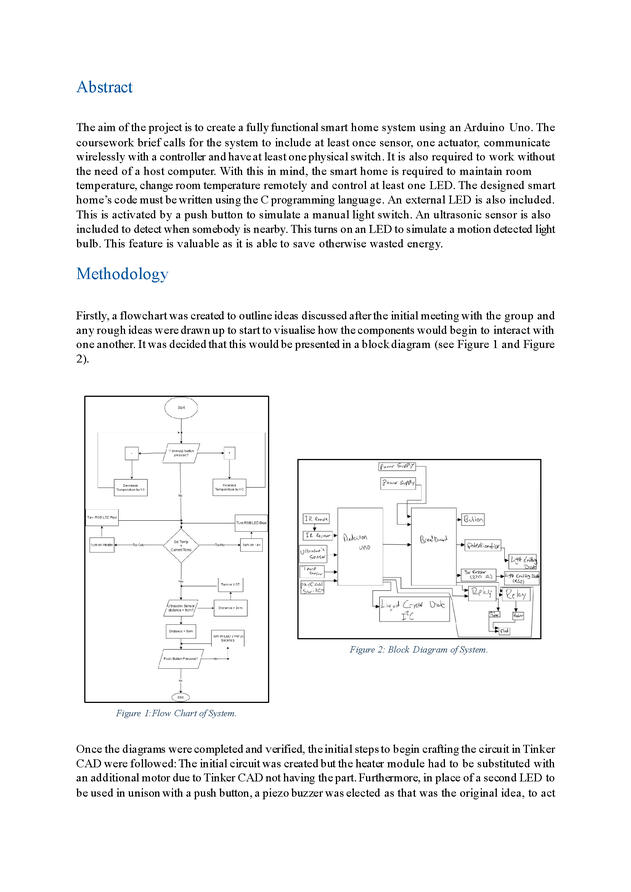

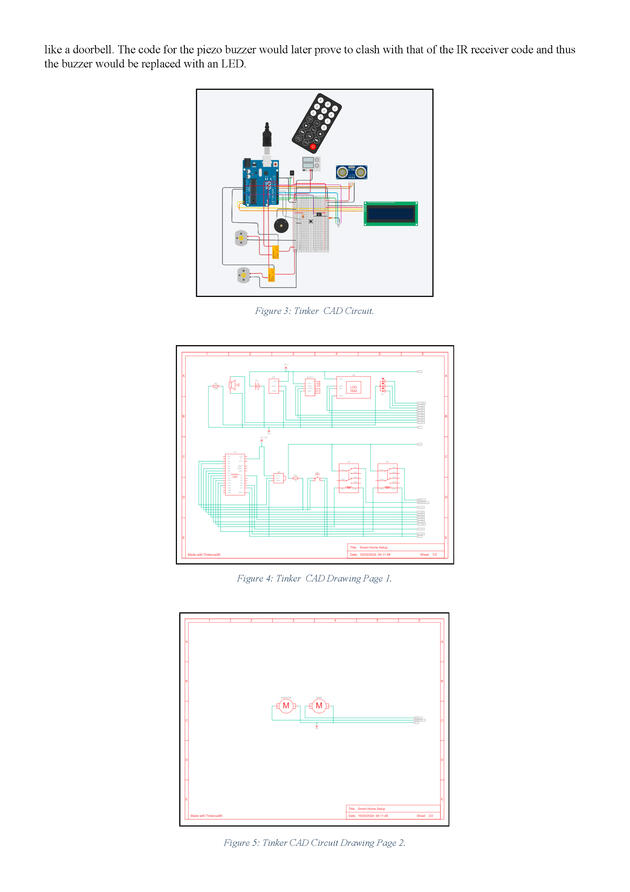

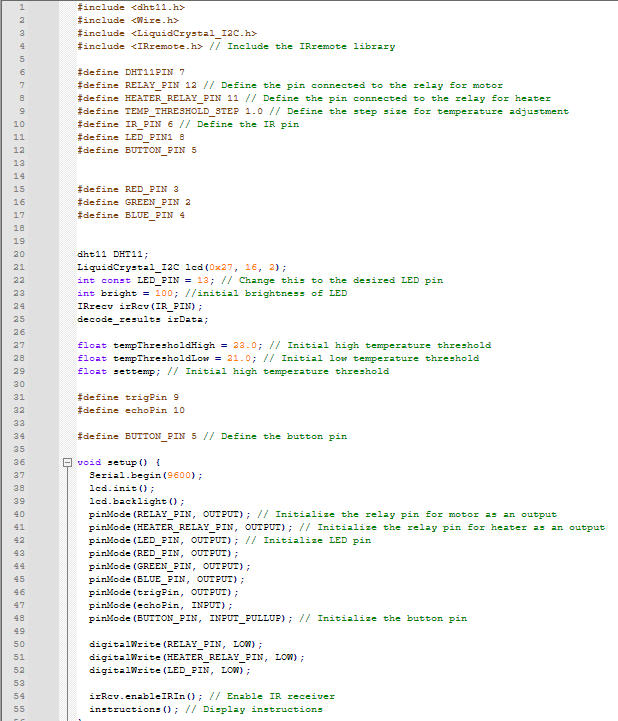

Smart home system Designed an Arduino based setup with sensors and actuators, produced block and flow diagrams, code and tests for temperature control.

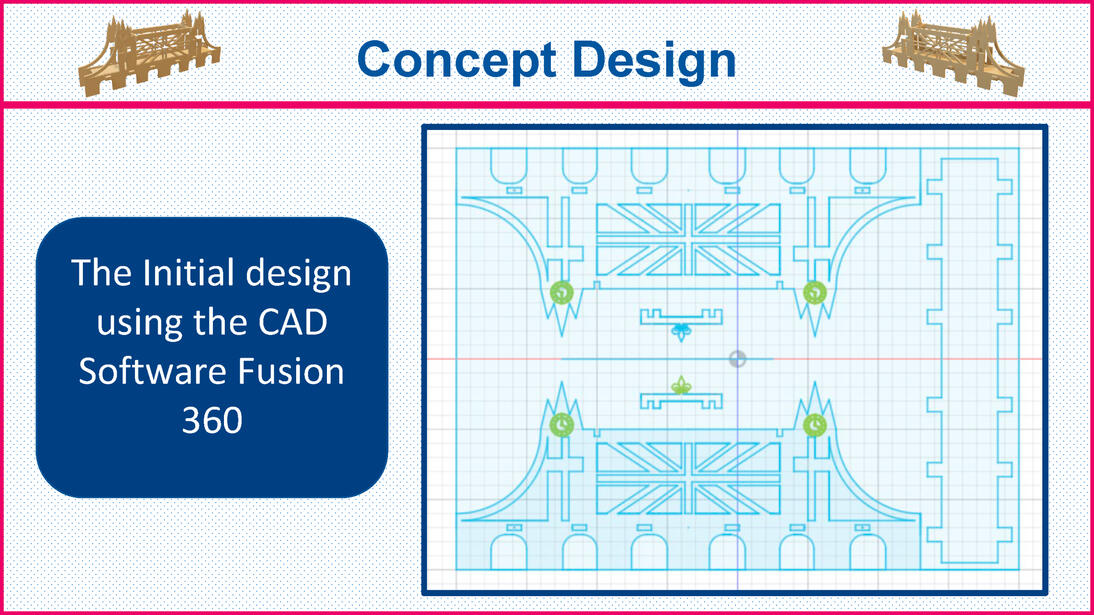

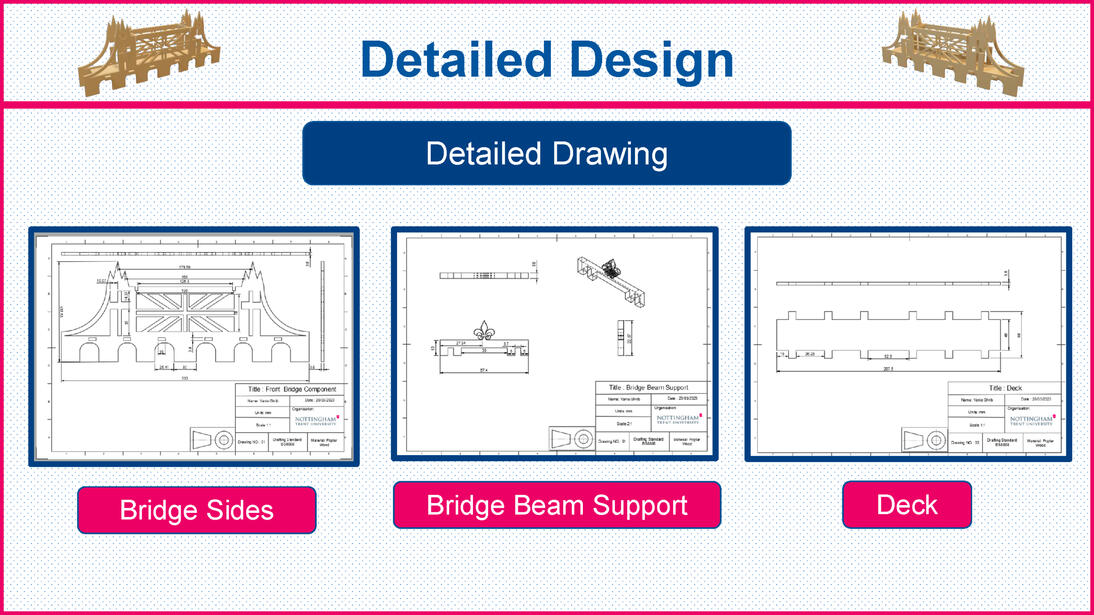

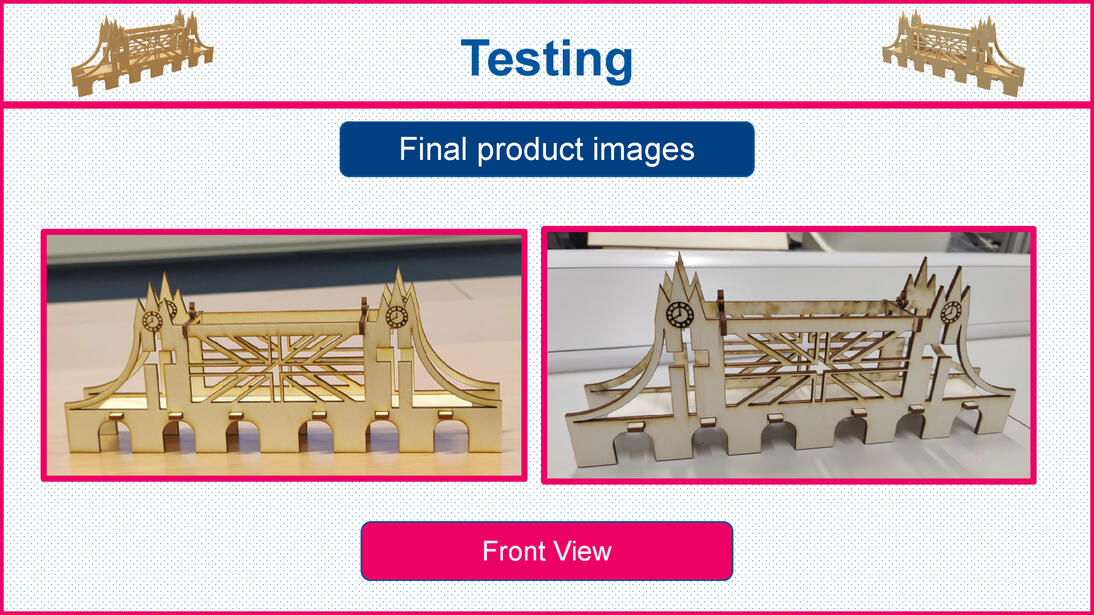

Laser cut bridge Designed an interlocking bridge from a single 400 x 300 mm sheet, produced drawings with DfM notes, manufactured and verified fit and assembly.

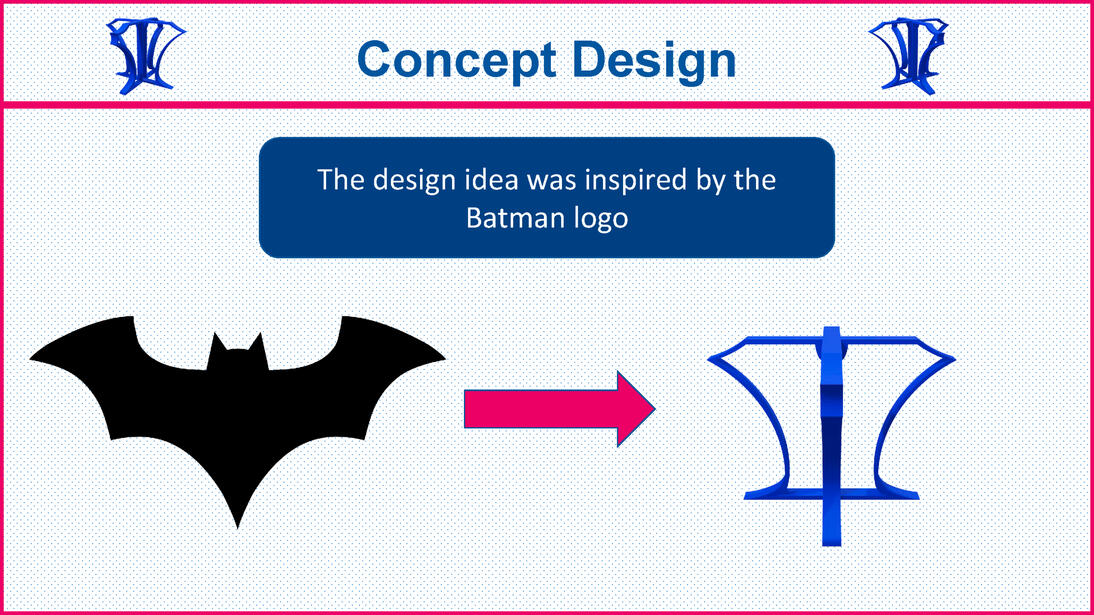

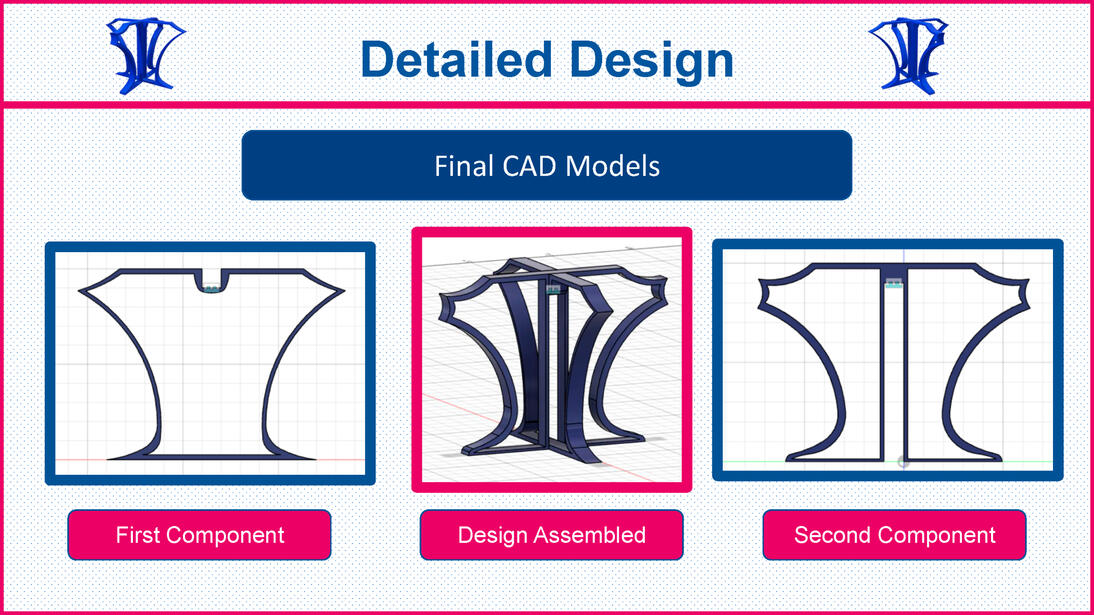

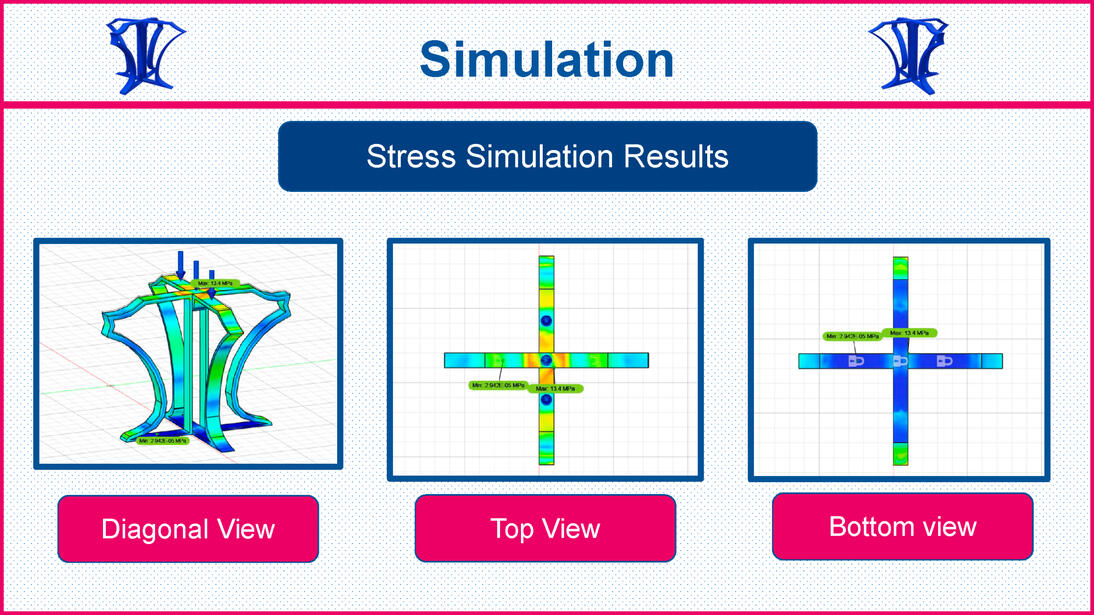

3D printed pier support Optimised geometry in Fusion 360 and ran simulation for static loading, achieved a safety factor of at least 3 for a 5 kg load, printed a prototype and confirmed results with testing.

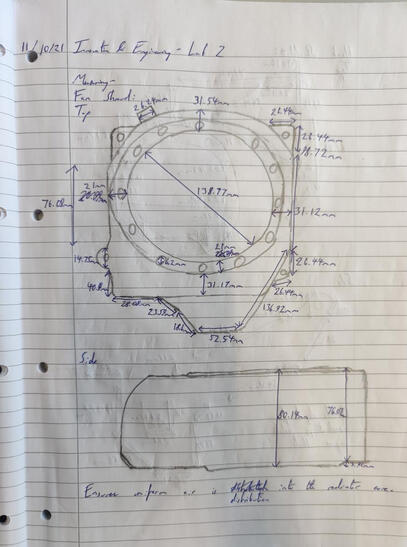

Honda 160 GP engine Reverse engineered by disassembly and measurement, created CAD models and drawings, reassembled and documented.

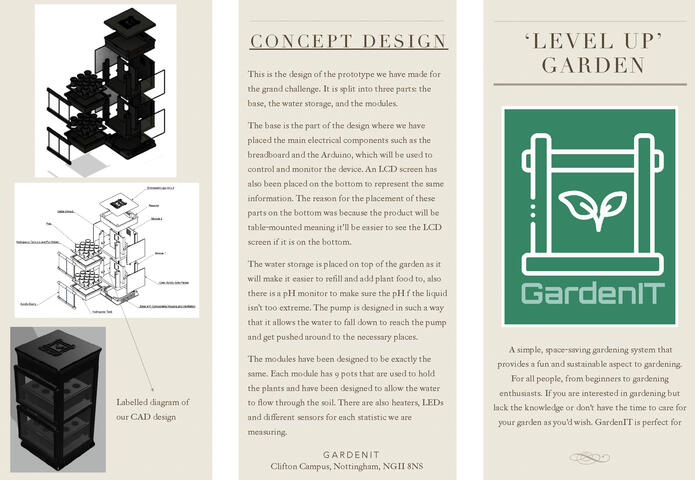

Smart garden automation Built a working prototype controlling pH, temperature, humidity and light, presented to an academic panel and received an award.

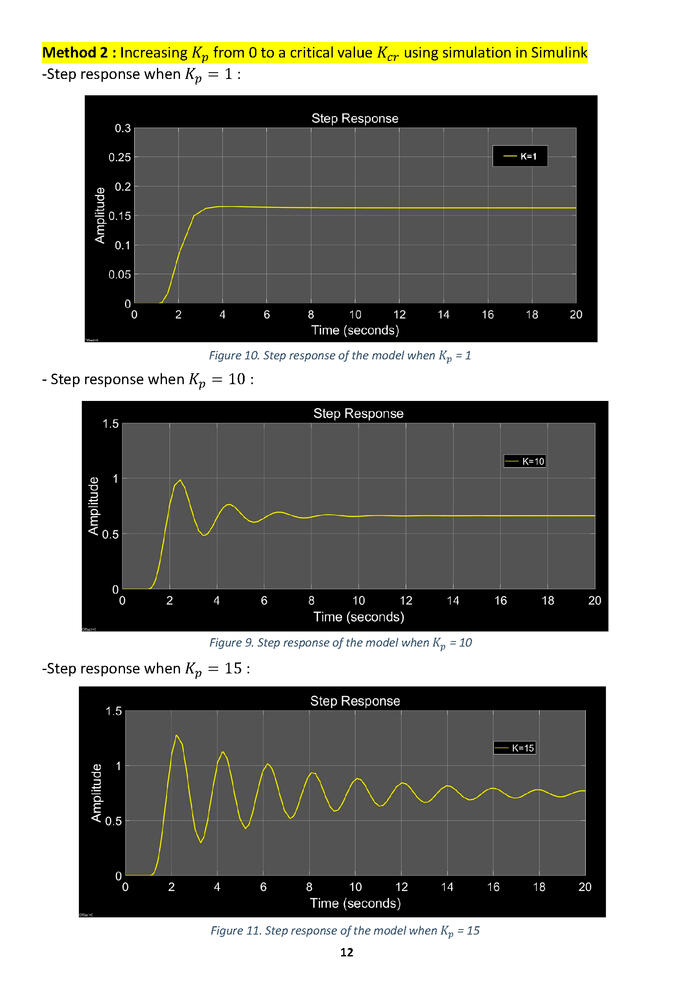

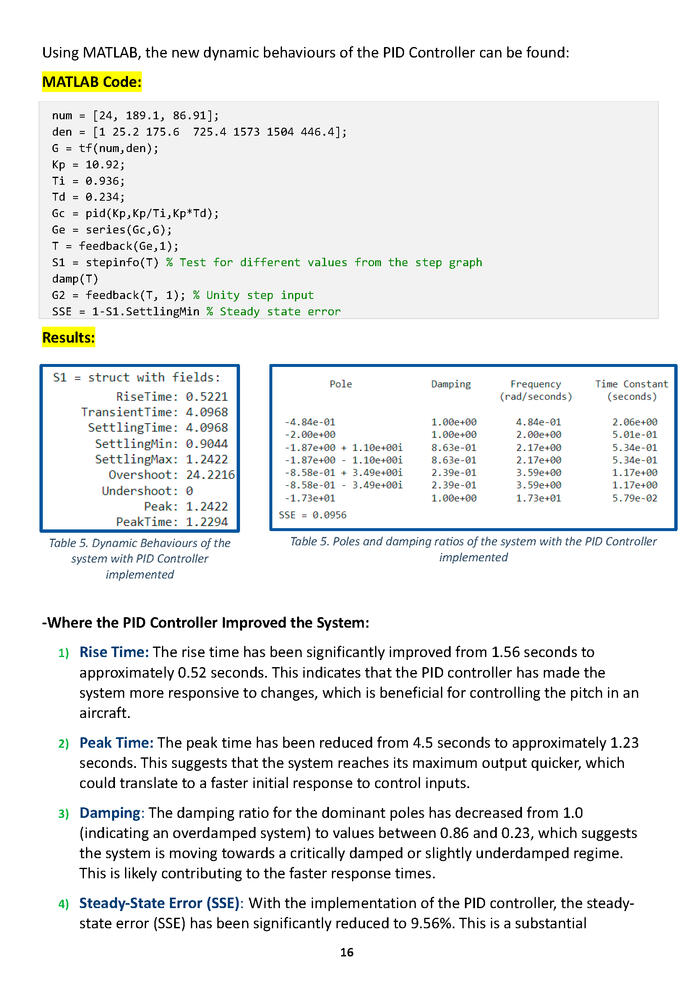

Control systems Built a plant model in MATLAB and Simulink, derived the transfer function and tuned a PID controller to improve settling and overshoot.

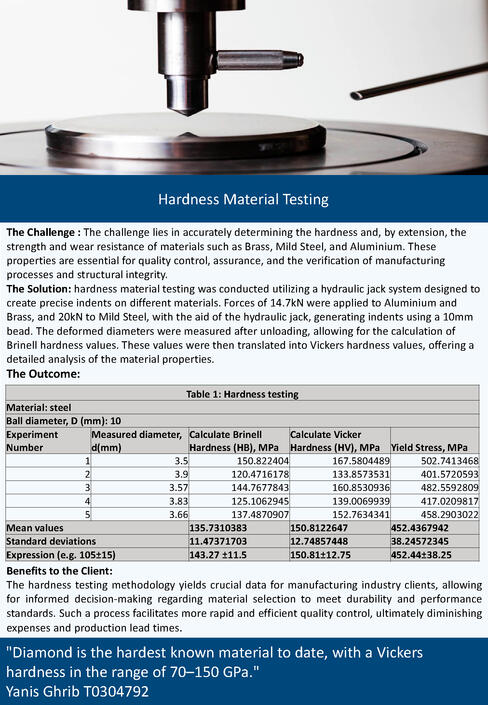

Materials and manufacturing Performed tensile, hardness, fatigue and creep tests, analysed results and wrote client style summaries, prepared CAM in Fusion 360 for CNC machining and planned 3D printing runs.

aBOUT

Work Methodology

In new roles, I first focus on understanding the company’s profit drivers and the technical knowledge required to sustain and improve them.After that, I clarify deliverables, timelines, and the broader purpose of my role so I have the ability to approach requirements from different angles if deemed fit.I then try to plan my work within a specific timeline while anticipating future requirements to deliver scalable and replicable solutions while also minimising reliance on inputs from other teams to increase flexibility and avoid unexpected delays.

Contact

I am based in Nottingham, UK, and welcome opportunities for professional discussions in the field of Engineering.

You can reach me via email at yanis@ghrib.co.uk or by phone at +(44) 7926 787817.

You can also connect with me on LinkedIn to explore more about my work and projects.